10 heating zones

Nitrogen soldering process

Weight APPROX:2615KG

Dimension 6135*1360*1490mm

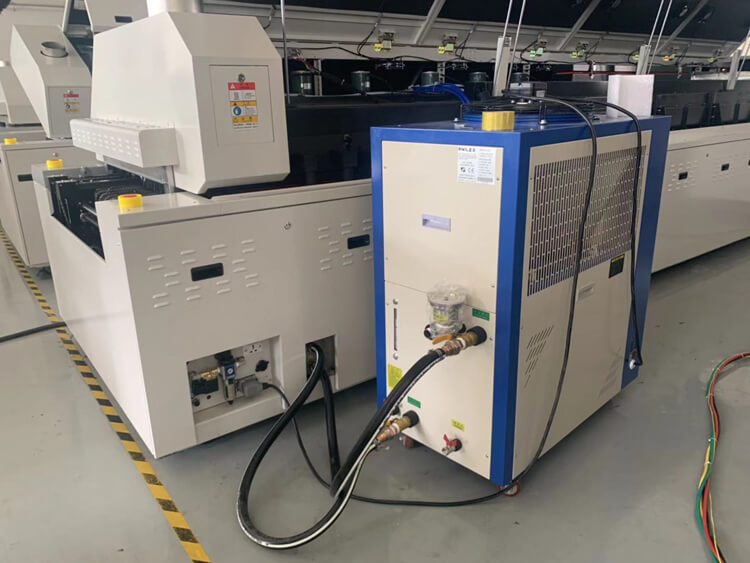

Product description: 10 Zones Nitrogen SMT Reflow Oven KTE 1000-N, 10 heating zones, Nitrogen soldering process, Weight APPROX:2615KG, Dimension 6135*1360*1490mm

10 Zones Nitrogen SMT Reflow Oven KTE 1000-N

10 Zones Nitrogen SMT Reflow Oven KTE 1000-N

Features:

1. Totally meet various requirements for the lead free processing.

2. WindowsXP operation system, Chinese/English can be swtiched online.

3. Standard air oven, Patent air system, using hot air convection conduction heat faster, more efficient compensation.

4. PLC+PID closed loop control to achieve high prectise temperature control and repeatable profiles.

5. Dual temperature sensors and dual safety control, system shall cut off the power while abnormal alarm.

6. Modular design to get quick and simple maintenance so that reducing the maintenance time & cost.

7. The temperature inspection instrument constantly monitors the temperature of each temperature zone, ultra-high temperature protection, and

automatically switch off the heating power

8. Nitrogen quantification is controllable throughout the process, and each temperature zone is independently closed-loop controlled, which can make

the nitrogen concentration range from 5-200ppm.

9. The new two-stage flux recovery system, multi-point collection, fully improves recovery efficiency and reduces maintenance time and frequency for customers.

Model | KTE-1000-N | Control | Industrial computer |

Heating zones qty. | Top 10, bottom 10 | Cooling zones qty. | Top 2 |

Heating zone length | 3892mm | Current plate structure | Galvanized plate |

Weight | APPROX:2615KG | Dimension | 6135*1360*1490mm |

Exhaust capacity | 10㎡/min×2 | Color | Grey |

Nitrogen system | |||

With "-N" standard configuration including nitrogen sealed structure and pipeline, nitrogen flow meter, water chiller cooling system | |||

Full Nitrogen system: Oxygen analyzer added on the N Standard | |||

Nitrogen consumption Standard width machine (400mm Width): 300-1000ppmO2ppm, 10-20m3/ hr | |||

N2 Consumption: Widening machine (610mm Width): 500-1000ppm at 25-30m3 / hr | |||

Control system | |||

Electricity supply | 3P 380V/220V 50/60HZ | Temp. control range | Room temp.~300℃ |

Total power | 80KW | Temp. control accuracy | ±1℃(static state) |

Start power | 36KW | Temp. control method | PID +SSR drive |

Consumption power | 12KW | PCB temperature deviation | ±1.5℃ |

Speed control | Inverter adjust | Data save | All profiles can be saved |

Warm up time | Apprx.30minute | Abnormal alarm | High, low temp. alarm |

Conveying system | |||

Rail structure | 2 Sectional structure | Rail fixed method | Front fix |

Chain | Stuck-free type | Conveying height | 900±20mm |

PCB Max. width | 50-400mm | Conveying method | Mesh+ chain |

Component height | Top/bottom 25mm | Conveying speed | 300-2000mm |

Conveying direction | Left to right | Lubrication | Automatic |

Cooling system | |||

Cooling method | Forced air cooling | ||

Heating features | |||

Heating zones | Top 10,bottom 10(3892mm)can meet the need of the peak lead-free technique. | ||

Cooling zones | After cool down by air, PCB temp. is ≤70℃ at the exit. | ||

Warm up time | From the normal temp. to set temp, approximate 30 minutes. | ||

Warm up sequence | Warm up from two side, save the power and time | ||

Profile transfer time | <15min | ||

Heating zone temp. control accuracy | ±1℃ | ||

PCB temp. deviation | ±1.5℃ | ||

Empty to full load heat balance respond time | ≤20 s | ||

Keyword:

JUKI RS-1R pick and place machine, JUKI RX-7R pick and place machine, Hanwha SM481 Plus Pick and Place Machine, SMT pick and place machine, JUKI Pick and place Machine, Samsung Pick and Place Machine, Yamaha Pick and Place Machine, Panasonic Pick and Place Machine, FUJI Pick and Place Machine, Siemens Pick and Place Machine.

Shenzhen Qituo electronic Co., Ltd provide a full SMT assembly line solutions, including SMT Reflow Oven, Wave Soldering Machine, Pick and Place Machine, SMT Stencil Printer, SMT AOI SPI Machine, SMT Peripheral Equipment, SMT Assembly line, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: wechat whatsapp:+8617748683433, Email: sales@qismt.com

FAQ

1) This is the first time I use this kind of machine, is it easy to operate?

There is English manual or guide video that show you how to use machine.

If you still have any question, please contact us by e-mail / skype/ phone /trademanager online service.

PREVIOUS:8 Zones Nitrogen SMT Reflow Oven KTE 800-N

NEXT:10 Zones Lead Free SMT Reflow Oven KTR-1000

Contact:Andy

Phone:17748683433

E-mail:sales@qismt.com

Add: