YAMAHA YRP10 SMT Stencil Printer

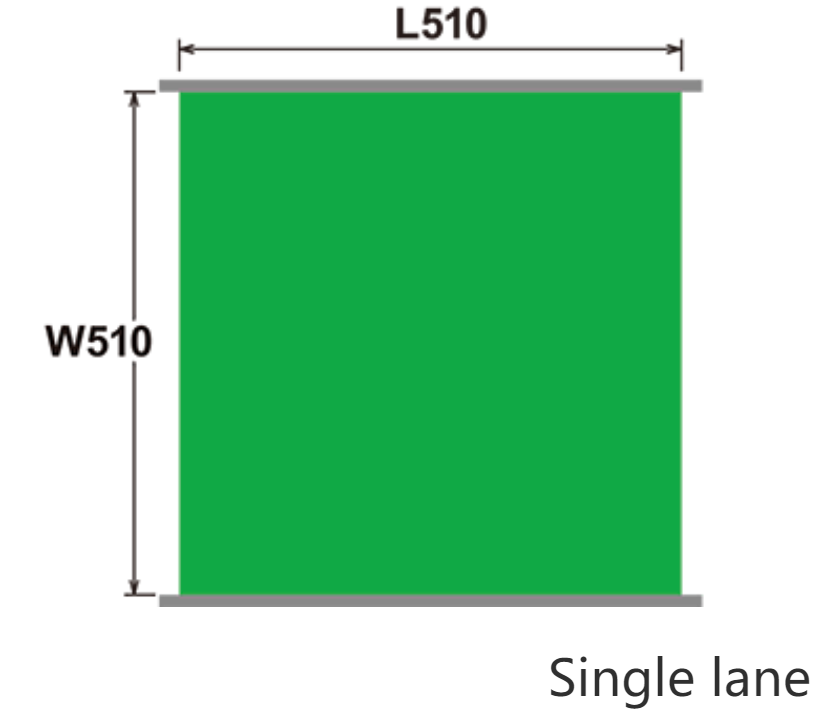

PCB Max Size:510X510mm

Positioning repeatdbility (±6σ) : ±8 μm Cp≧2.0

Printing accuracy (μ±6σ) : ±16 μm Cpk≧2.0Note

size: L1,640 x W1,840 x H1,525mm (Single-lane standard specification)

Weight:1710Kg

YAMAHA YRP10 SMT Stencil Printer

YAMAHA YRP10 SMT Stencil Printer

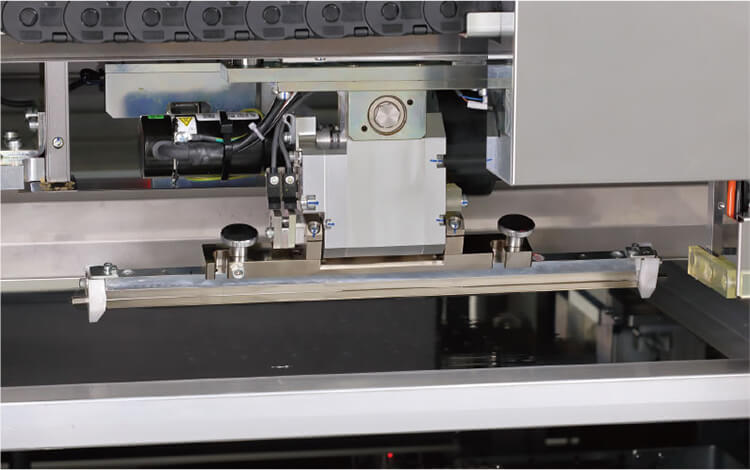

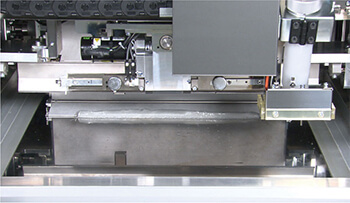

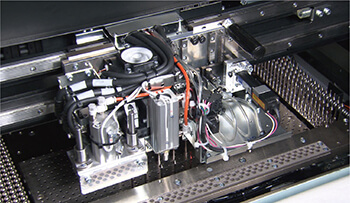

Program change squeegee attack angle and speed to an ideal setting to provide optimal printing conditions that match the solder being used.

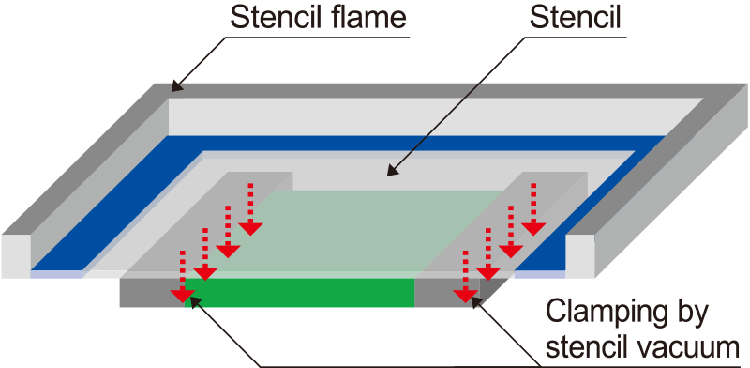

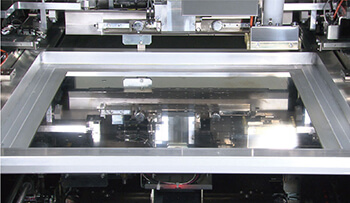

A stencil vacuum mechanism delivers consistent high accuracy printing with no effects from stencil droop. Also drastically cuts the setup time since no offset entry is needed during back and forth printing movement.

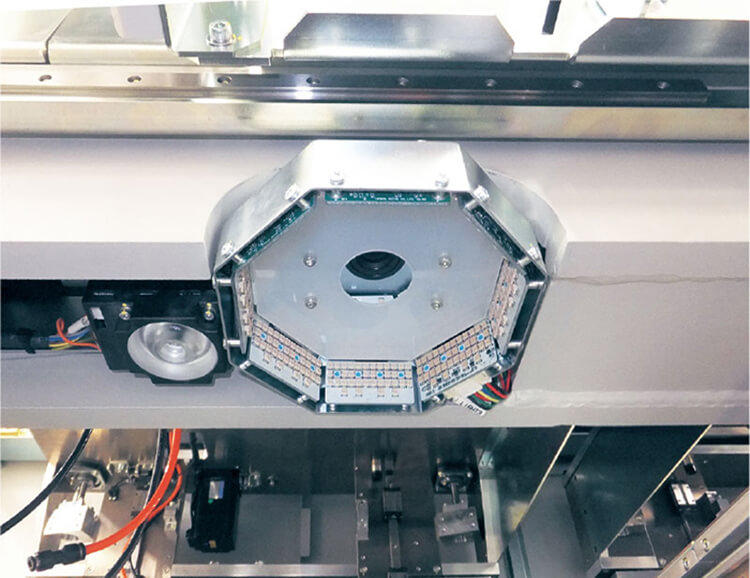

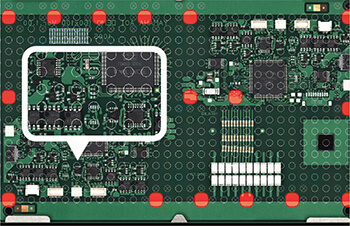

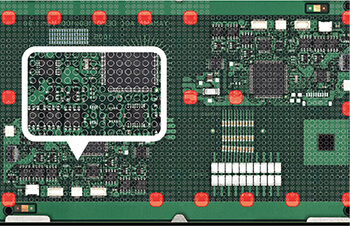

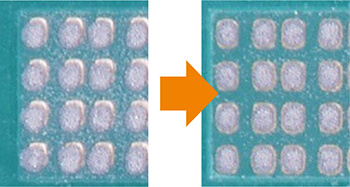

Supports full-on pro-level inspections with a dedicated camera. Feedback from inspection results allow over-printing and stencil cleaning.

Possible to arrange up to 200 pins. In addition to a 5 mm-pitched matrix plate, a 2.5 mm-pitched matrix plate with a higher degree of arrangement freedom is also available as an option.

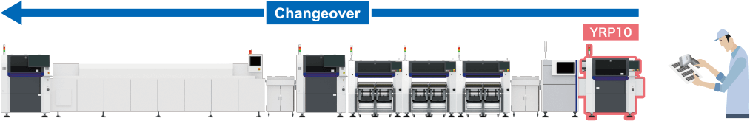

Ultra-high-efficiency support of a variety of production models

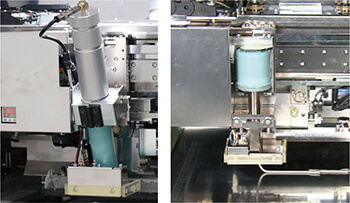

Automatic replacement of the stencil and push-up pins. Through a combination with automatic changeovers in the entire line, man-hours and the number of human errors in model changeover have been drastically reduced. Nonstop solder supply with a 12 oz. syringe achieves prolonged, unmanned, nonstop solder printing.

Stencil replacement

Supports multiple stencil sizes

To be performed in parallel with push-up pin replacement

Solder transfer

Solder rolling state is maintained

Prevention of solder dripping from squeegee

Push-up pin exchange

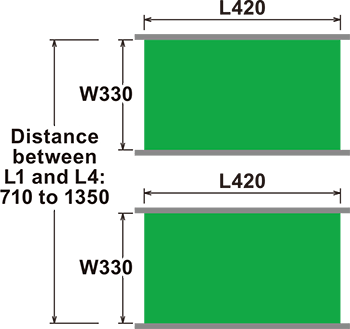

Capable of handling a large PCB (L420 x W420 mm)Note

Two-head simultaneous pickup high-speed pin replacement

Note

The 2.5mm pitch spec handles Max. L420 x W250mm PCBs.

L420 x W420mm size is also available as an option.

Solder supply

Possible to use a 6 oz. syringe and 12 oz. syringe together

Stabilized solder rolling radius

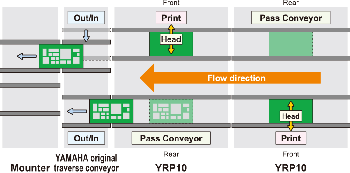

Dual lane fully independent production

Flexible dual lane

Connecting two YRP10s in series enables a fully

independent dual-lane operation. A dual-lane

operation and an automatic changeover feature are

supported at the same time. Addition of a traverse

conveyor flexibly connects the YRP10s to the

downstream

equipment.

W330 dual lane

Large PCBs the size of up to L420 × W330 mm can be produced in a dual lane. You can increase the number of PCBs to take and the number of PCBs to be conveyed by the carrier, boosting production efficiency.

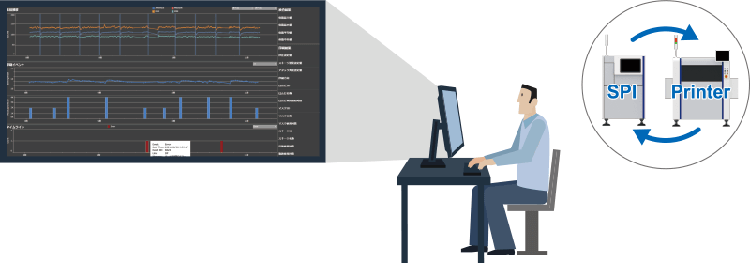

M2M link solution

Inspection result feedback

Possible to clean the stencil and correct its position

using inspection result feedback via the link with the SPI.

Solder paste printing analysis

Displays link between fluctuations in solder size and solder paste printing status and allows checking the solder paste printer status when defects or problems occur. Streamline quality improvements and line operating rate.

YAMAHA YRP10 SMT Stencil Printer | |

Applicable PCB | Single lane : L510 x W510mm to L50 x W50mm |

Dual lane : L420 x W330mm to L50 x W50mm | |

Printing heads | 3S head (3S : Swing Single Squeegee) |

Printing accuracy | Positioning repeatdbility (±6σ) : ±8 μm Cp≧2.0 |

Printing accuracy (μ±6σ) : ±16 μm Cpk≧2.0Note | |

Core cycle time (Not include printing) | 6sec |

Applicable stencil size | L750 x W750mm, L736 x W736mm (29″), L750 x W650mm, L650 x W550mm |

L600 x W550mm, L550 x W650mm, L584 x W584mm (23″) | |

Power supply | Single-phase AC 200 to 230V +/-20V |

Air supply source | 0.4MPa or more |

External dimension | L1,640 x W1,840 x H1,525mm (Single-lane standard specification) |

Weight | 0.4MPa or more Printer : Approx. 1,710kg |

Keyword:

JUKI RS-1R pick and place machine, JUKI RX-7R pick and place machine, Hanwha SM481 Plus Pick and Place Machine, SMT pick and place machine, JUKI Pick and place Machine, Samsung Pick and Place Machine, Yamaha Pick and Place Machine, Panasonic Pick and Place Machine, FUJI Pick and Place Machine, Siemens Pick and Place Machine.

Shenzhen Qituo electronic Co., Ltd provide a full SMT assembly line solutions, including SMT Reflow Oven, Wave Soldering Machine, Pick and Place Machine, SMT Stencil Printer, SMT AOI SPI Machine, SMT Peripheral Equipment, SMT Assembly line, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: wechat whatsapp:+8617748683433, Email: sales@qismt.com

FAQ

1) This is the first time I use this kind of machine, is it easy to operate?

There is English manual or guide video that show you how to use machine.

If you still have any question, please contact us by e-mail / skype/ phone /trademanager online service.

2) If machine have any problem after I receive it, how can I do ?

Free parts send to you in machine warranty period.

If the part is less than 0.5KG, we pay the postage.

If it exceeds 0.5KG, you need to pay the postage.

3) MOQ ?

1 set machine, mixed order is also welcomed.

4) How can I buy this machine from you? ( Very easy and flexible !)

A. Consult us about this product on line or by e-mail.

B. Negotiate and confirm the final price , shipping , payment methods and other terms.

C. Send you the proforma invoice and confirm your order.

D. Make the payment according to the method put on proforma invoice.

E. We prepare for your order in terms of the proforma invoice after confirming your full payment.

And 100% quality check before shipping.

F.Send your order by air or by sea.

5)Why choose us ?

A. Gold supplier on Alibaba !

B. Trade assurance to US$54,000 !

C. Best price & Best shipping & Best service !

Contact:Andy

Phone:17748683433

E-mail:sales@qismt.com

Add: