Yamaha YRM20DL Pick and Place Machine

Speed:120,000CPH

Component range:0201 mm to W 12 x L 12 mm

Weight:2550KG

Dimension:L 1,374 x W 2,102 x H 1,445 mm

Yamaha YRM20DL Pick and Place Machine

Yamaha YRM20DL Pick and Place Machine

Yamaha YRM20DL Pick and Place Machine

1 head solution provides broad-range production capability

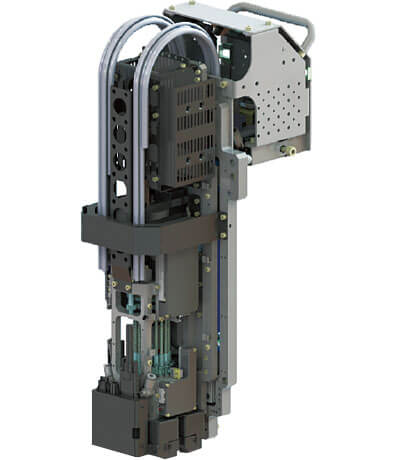

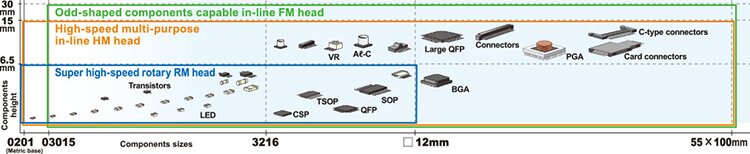

1.Super high-speed rotary RM head achieves 120,000CPH

Rotary head boosts component mountability of tiny components. This maintains high speed production since head replacements are no longer needed. This is technology that helps carry on the 1 head solution concept. This head can handle components ranging from super-tiny 0201mm components on up to medium-sized odd-shaped components of 12 x 12mm dimensions with heights of 6.5mm

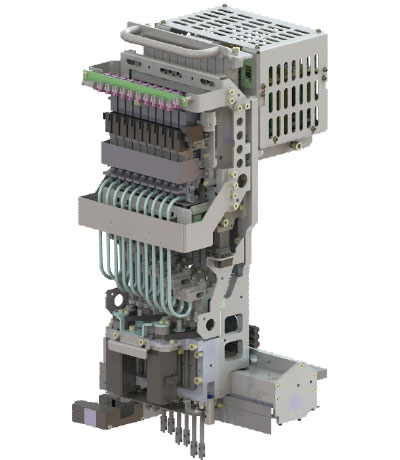

2.High-speed multi-purpose in-line HM head

The flexible “all-around” head not only has high-speed, but also has the versatility essential for mounting super-tiny 0201mm components all the way up to large-size components of 55 x 100mm and heights up to 15mm.

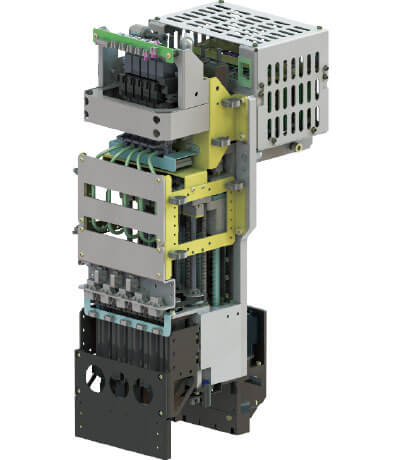

3.Odd-shaped components capable in-line FM head

The ultra-wide-range head fully handles components ranging from super-tiny 03015mm chips on up to ultra-large components of 55 x 100mm and heights of 30mm. Force control is also available.

RM head / HM head / FM head

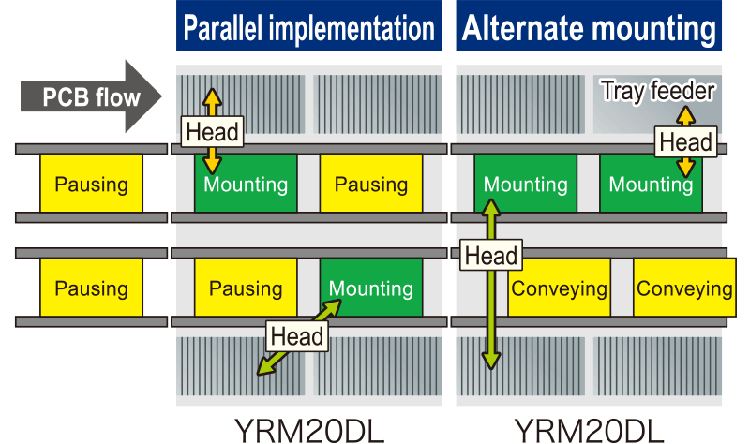

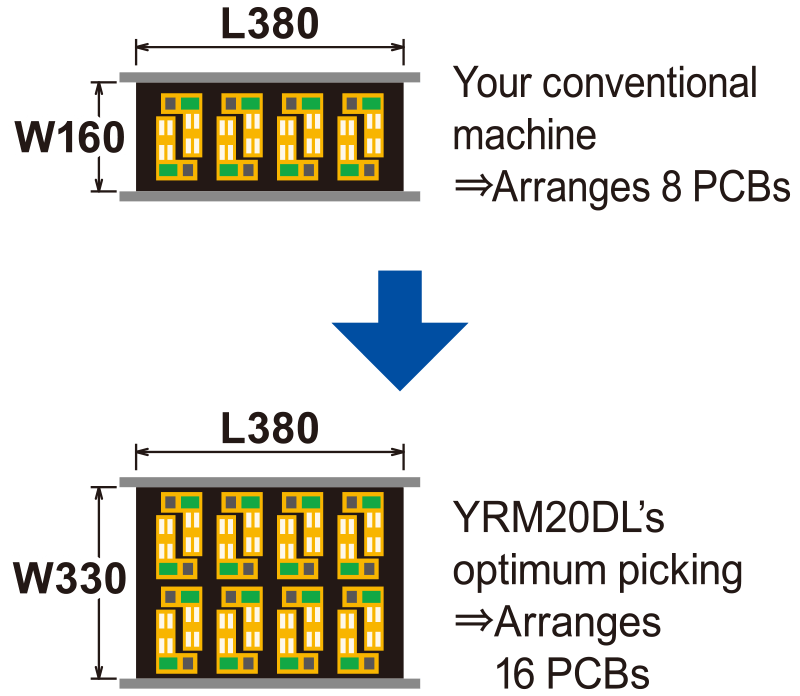

Takes on various types of production with super high efficiency

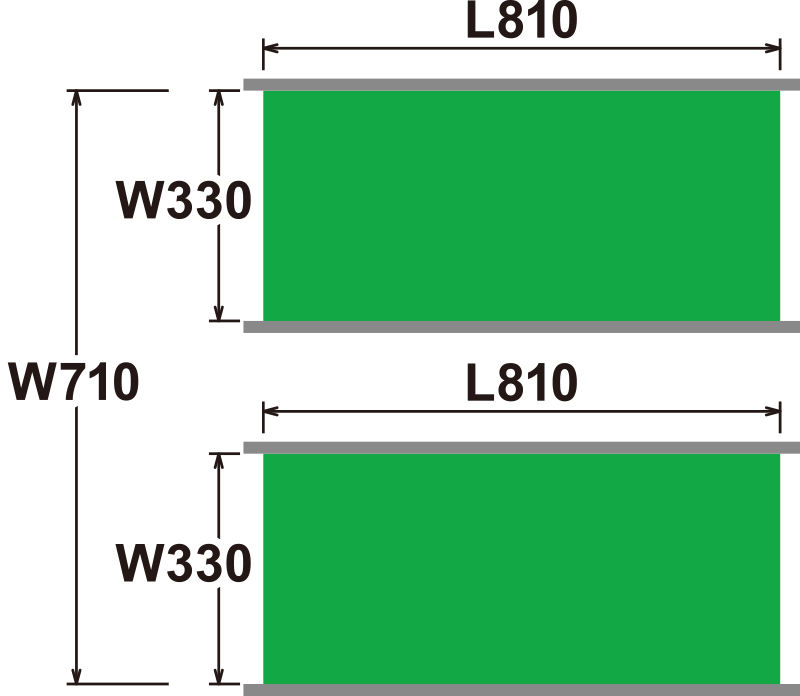

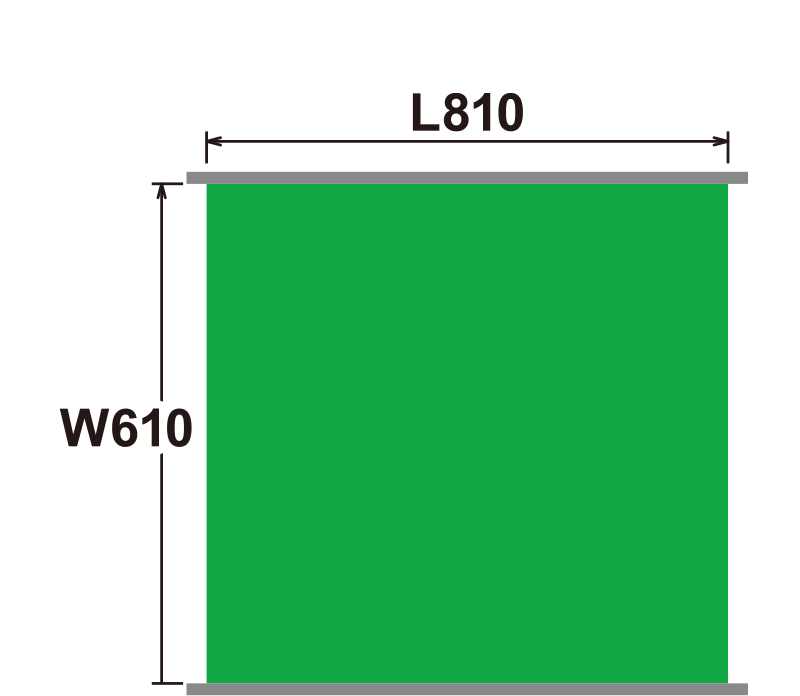

W330mm Dual lane

Produces L-size PCB of up to L810×W330mm in Dual-lane. Can increase PCBs to be picked up and carriers transported, raising production efficiency.

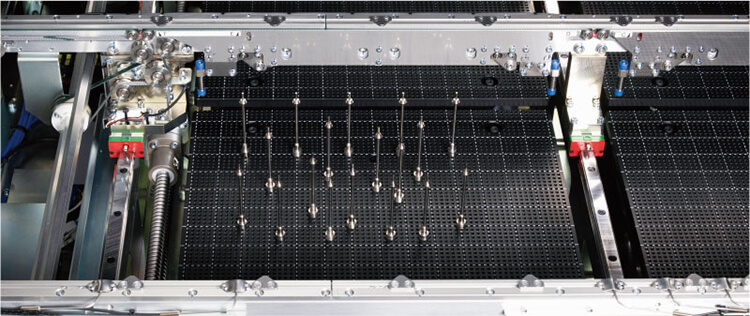

Automatic push-up pin exchange system Included in the automotive PKG

This automatically positions the pushup pins. Using along with the automatic program change over function drastically reduces the workload during production changeovers.

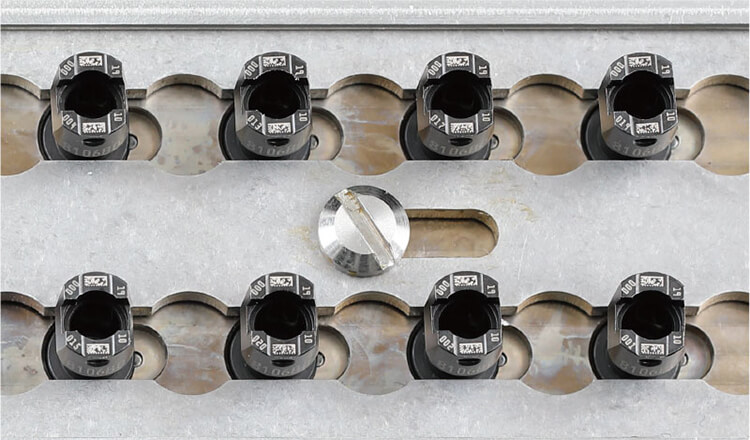

Auto nozzle station Included in the automotive PKG

The nozzle is automatically exchanged for efficient production. The nozzle holder can be exchanged with a single touch which makes setup and maintenance easy.

High accuracy mounting and steady production of micro components

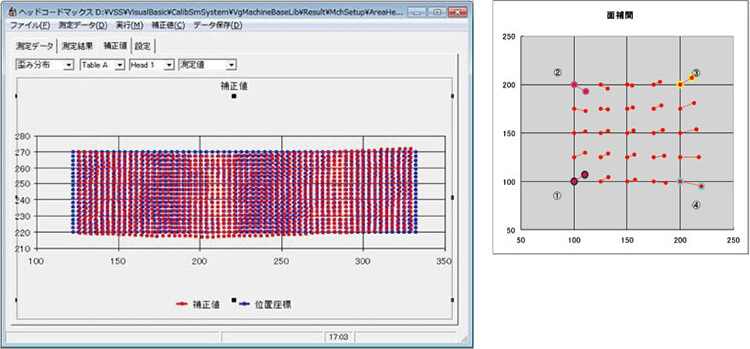

High accuracy mounting level of ±15μm (Cpk≧1.0)

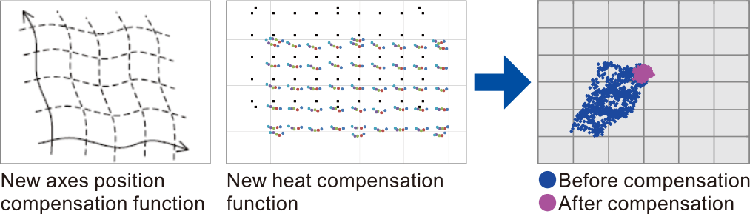

Machine vibration controlled with a very stiff base, etc., and adjustment accuracy improved with Coord MACS, achieving a high accuracy mounting level of ±15μm.

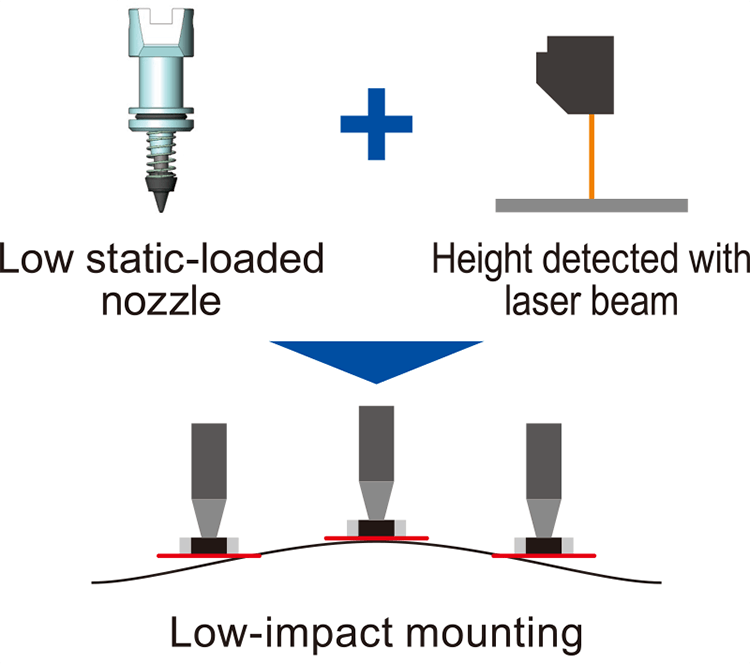

Low-impact mounting

Relative height of the mounting surface and component bottom controlled by measuring PCB height to control mounting height, which minimizes impact on micro components together with a low static-loaded nozzle.

Steady pick-up and mounting

Multiple Accuracy Compensation System “MACS” realises stable pick-up and mounting by recognizing correction marks in the machine during production.

High-efficiency production with various features

Non-stop tray feeder eATS30

High-capacity tray feeder that can store up to 30 pallets. Provides a non-stop supply of tray components, achieving non-stop production. The lineup also includes a 10-stage tray component feeder “cATS10R” as well, with excellent space savings and cost performance.

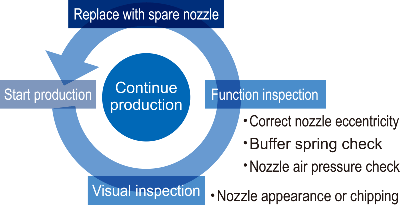

Nozzle and feeder maintenance warnings

Self-diagnosis and self-recovery functions continuously maintain nozzles and feeders in a clean state for continuous high-quality production.

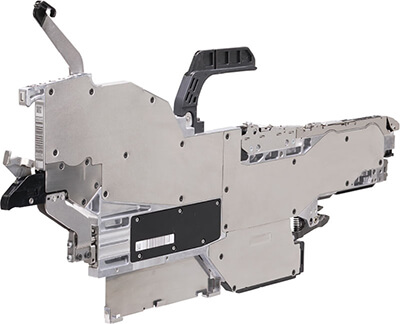

Auto loading feeder

.

.

A simple task of cutting and inserting a tape reduces the load in the component supply work. Setting two reels makes it possible to level off the component supply timing, minimizing the risk of line stoppage due to failure of component supply.

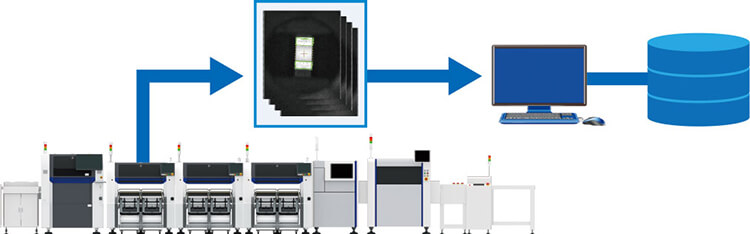

The side-view camera improves quality for mounting of tiny components. Coplanarity checker can also be installed as an option. All Image Tracer Plus (option) saves every component recognition image, providing strong support for analysis of the mounting quality.

Keyword:

JUKI RS-1R pick and place machine, JUKI RX-7R pick and place machine, Hanwha SM481 Plus Pick and Place Machine, SMT pick and place machine, JUKI Pick and place Machine, Samsung Pick and Place Machine, Yamaha Pick and Place Machine, Panasonic Pick and Place Machine, FUJI Pick and Place Machine, Siemens Pick and Place Machine.

Shenzhen Qituo electronic Co., Ltd provide a full SMT assembly line solutions, including SMT Reflow Oven, Wave Soldering Machine, Pick and Place Machine, SMT Stencil Printer, SMT AOI SPI Machine, SMT Peripheral Equipment, SMT Assembly line, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: wechat whatsapp:+8617748683433, Email: sales@qismt.com

FAQ

1) This is the first time I use this kind of machine, is it easy to operate?

There is English manual or guide video that show you how to use machine.

If you still have any question, please contact us by e-mail / skype/ phone /trademanager online service.

2) If machine have any problem after I receive it, how can I do ?

Free parts send to you in machine warranty period.

If the part is less than 0.5KG, we pay the postage.

If it exceeds 0.5KG, you need to pay the postage.

3) MOQ ?

1 set machine, mixed order is also welcomed.

4) How can I buy this machine from you? ( Very easy and flexible !)

A. Consult us about this product on line or by e-mail.

B. Negotiate and confirm the final price , shipping , payment methods and other terms.

C. Send you the proforma invoice and confirm your order.

D. Make the payment according to the method put on proforma invoice.

E. We prepare for your order in terms of the proforma invoice after confirming your full payment.

And 100% quality check before shipping.

F.Send your order by air or by sea.

5)Why choose us ?

A. Gold supplier on Alibaba !

B. Trade assurance to US$54,000 !

C. Best price & Best shipping & Best service !

Contact:Andy

Phone:17748683433

E-mail:sales@qismt.com

Add: