Standard cycle time: 6.5 seconds + process

Maximum printing surface: 510 mm (X) × 508,5 mm (Y)

Weight: Approx. 690 kg

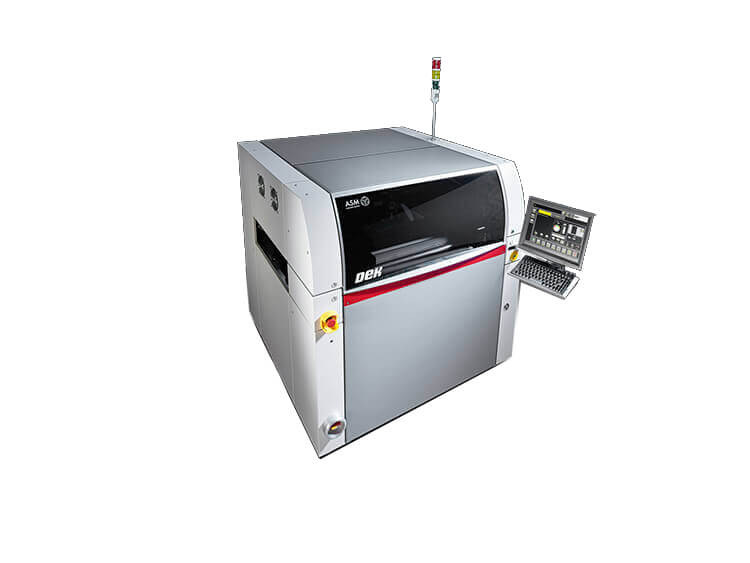

Product description: DEK NeoHorizon SMT Stencil Printer, Standard cycle time: 6.5 seconds + process, Maximum printing surface: 510 mm (X) × 508,5 mm (Y), Weight: Approx. 690 kg

DEK NeoHorizon SMT Stencil Printer

DEK NeoHorizon SMT Stencil Printer

DEK NeoHorizon

With its modular design, the latest generation of our powerful screen printers is customizable for any customer-specific or application-specific requirements. Clamping systems, conveyors, tooling, paste management, verification – the DEK NeoHorizon can be equipped and/or retrofitted with many powerful and precision-enhancing options. All this flexibility can be controlled easily and comfortably with the leading printer software: DEK Instinctiv™ V9.

Two basic printer configurations are available: The DEK NeoHorizon 03 iX with the DEK HawkEye 750 camera system, semi-automatic stencil load and the IUSC understencil cleaning system features a core cycle time of 8.0 seconds and a machine accuracy of ±20 µm @ 2 Cmk for use in high-mix environments. The DEK NeoHorizon 01 iX with its core cycle time of 6,5 seconds and enhanced machine accuracy of ±15 µm @ 2 Cmk was designed for applications with particularly high demands on quality and throughput, for example for 0201 (metric) components. This configuration is equipped with the high-resolution DEK HawkEye 1700 camera, a fully automatic stencil alignment system, and the high-end DEK Cyclone understencil cleaning system.

Back-to-back: Single-track, dual-track, and back to single-track

The innovative design of the new printer and its especially robust cover make it possible to perform all control and maintenance operations from the front of the machine. As a result, you can now position two DEK NeoHorizons back-to-back for a dual-track solution that’s smart, flexible and future-proof. The two machines can nevertheless be configured and operated independently of each other. And when the dual-track solution is no longer needed, you simply separate the two printers and use them on separate lines again. The perfect combination of flexibility and investment protection.

Technical Data:

Standard configuration | DEK NeoHorizon 01iX | DEK NeoHorizon 03iX |

Machine alignment capability | ± 12.5 μm @ 2.0 Cmk (6 sigma) | ± 12.5 μm @ 2.0 Cmk (6 sigma) |

Machine alignment accuracy | ± 15 μm @ 2.0 Cmk (± 6 sigma) | ± 20 μm @ 2.0 Cmk (± 6 sigma) |

Process alignment accuracy | ± 20 μm @ 2.0 Cpk (6 sigma)# | ± 25 μm @ 2.0 Cpk (6 sigma)# |

Standard cycle time | 6.5 seconds + process | 8 seconds + process |

Maximum printing surface | 510 mm (X) × 508,5 mm (Y) | |

User interface | Touchscreen, keyboard and trackball, | |

Camera | DEK HawkEye 1700 digital camera | DEK HawkEye 750 digital camera |

Squeegee adjustment | Motorized with squeegee pressure feedback | |

Stencil loading | Automatic, incl. squeegee drip catcher | Semi-automatic,incl. squeegee drip catcher |

Stencil alignment | Motorized (actuators); aligned on | Motorized (actuators); aligned in |

DEK ProFlow | Optional | |

Understencil Cleaning | DEK Cyclone 300 mm/400 mm/515 mm | DEK IUSC 300 mm/400 mm/520 mm |

Technical documentation | Printed documents: User manual, installation instructions, circuit diagrams. | |

Compressed air supply | 5-8 bar at ~5 litres/minute | |

Power supply | 100 Volts to 240 Volts ±10 %. Single phase 50/60 Hz | |

Weight | Approx. 690 kg depending on selected options | |

* The machine and repeat accuracy check will be conducted using production-typical process variables. The repeat accuracy rating comprises the printing speed, squeegee operation, table movements and camera movements. | ||

Keyword:

JUKI RS-1R pick and place machine, JUKI RX-7R pick and place machine, Hanwha SM481 Plus Pick and Place Machine, SMT pick and place machine, JUKI Pick and place Machine, Samsung Pick and Place Machine, Yamaha Pick and Place Machine, Panasonic Pick and Place Machine, FUJI Pick and Place Machine, Siemens Pick and Place Machine.

Shenzhen Qituo electronic Co., Ltd provide a full SMT assembly line solutions, including SMT Reflow Oven, Wave Soldering Machine, Pick and Place Machine, SMT Stencil Printer, SMT AOI SPI Machine, SMT Peripheral Equipment, SMT Assembly line, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: wechat whatsapp:+8617748683433, Email: sales@qismt.com

FAQ

1) This is the first time I use this kind of machine, is it easy to operate?

There is English manual or guide video that show you how to use machine.

If you still have any question, please contact us by e-mail / skype/ phone /trademanager online service.

2) If machine have any problem after I receive it, how can I do ?

Free parts send to you in machine warranty period.

If the part is less than 0.5KG, we pay the postage.

If it exceeds 0.5KG, you need to pay the postage.

3) MOQ ?

1 set machine, mixed order is also welcomed.

4) How can I buy this machine from you? ( Very easy and flexible !)

A. Consult us about this product on line or by e-mail.

B. Negotiate and confirm the final price , shipping , payment methods and other terms.

C. Send you the proforma invoice and confirm your order.

D. Make the payment according to the method put on proforma invoice.

E. We prepare for your order in terms of the proforma invoice after confirming your full payment.

And 100% quality check before shipping.

F.Send your order by air or by sea.

5)Why choose us ?

A. Gold supplier on Alibaba !

B. Trade assurance to US$54,000 !

C. Best price & Best shipping & Best service !

Contact:Andy

Phone:17748683433

E-mail:sales@qismt.com

Add: