FUJI SMT Screen Printer NXTR PM

Production range:610x610mm

Printing accuracy:±0.020 mm @6σ (CPK ≥ 2.0)

Weight:1600KG

Dimension:L1280 x W1700 x H1480mm

FUJI SMT Screen Printer NXTR PM

FUJI SMT Screen Printer NXTR PM

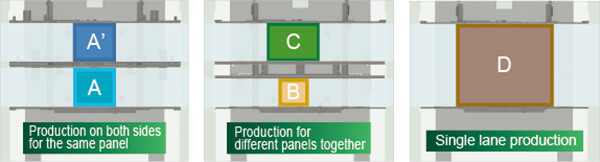

Support for single-lane and dual-lane production in one machine

A printer designed specifically for the FUJI NXTR with the right support for single and dual lane board transport in a single machine. This is

achieved without the use of “shuttle” systems, which significantly shortens the printer while still maintaining a large print image.

Printing at the correct position, with the correct amount, in the correct shape

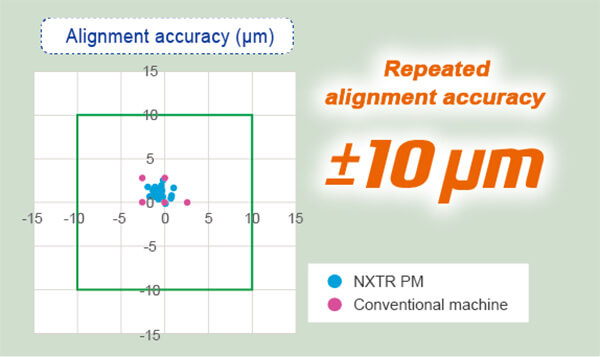

Repeated alignment accuracy ±10µm(6σ)

Better responsiveness to positioning the mask results from the lighter-weight offsetting mechanism with reduced sliding resistance in addition

to advanced image recognition accuracy for fine marks that is driven by the high resolution camera.

This brings a high level of alignment performance with stable printing quality.

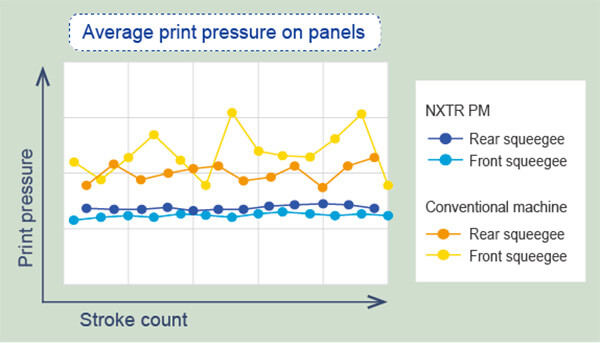

Using the appropriate print pressure

It is essential to apply the appropriate pressure to print the correct volume of solder. Our real-time print pressure feedback control and newly

developed squeegee head stabilize the print pressure at all times and maintain the angle of the squeegee edge.

This ensures the correct volume of solder.

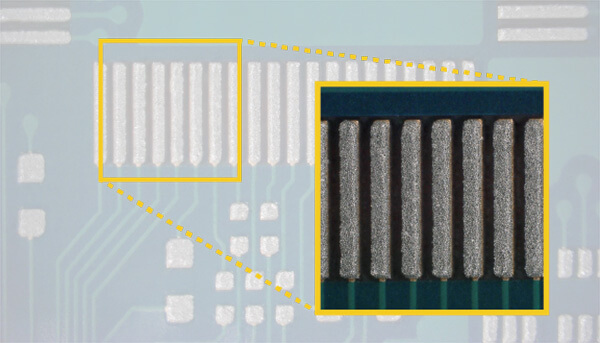

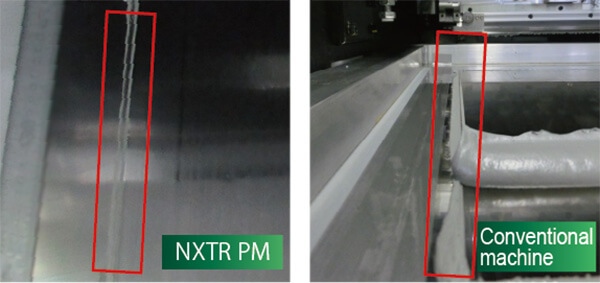

Printing shapes with sharp outlines

Taking into account the solder fluidity during snap-off, snap-off operation has optimized acceleration control.

This makes solder deposits in apertures transfer onto panels in the correct shape.

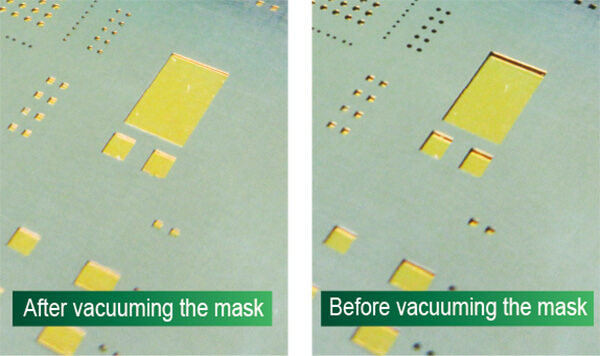

Reducing print deviations caused by stretched masks

The renewed vacuuming mechanism improves the panel and mask adhesion.

This eliminates print defects caused by stretched masks.

Preventing solder from escaping

The mechanism to reduce the amount of solder escaping from the printing squeegee lowers the volume of escaped solder substantially.

This leads to a higher rate of utilization of solder.

While this results in using fresh solder which furthers the stability of print quality, it also reduces solder collection and cleaning work.

No line stops for quality-related errors

Based on inspection result feedback from SPI machines, automatic offsetting is implemented in the printing conditions based on a prediction of future printing problems such as solder volume deviations, misalignment, and smearing.

This helps maintain high quality printing.

* Option

- Automatic mask positioning adjustment

- Mask condition visualization by mark camera

- Solder supply instructions

- Automatic cleaning

- Automatic production stops

Building production lines with the flexibility to handle various types of production

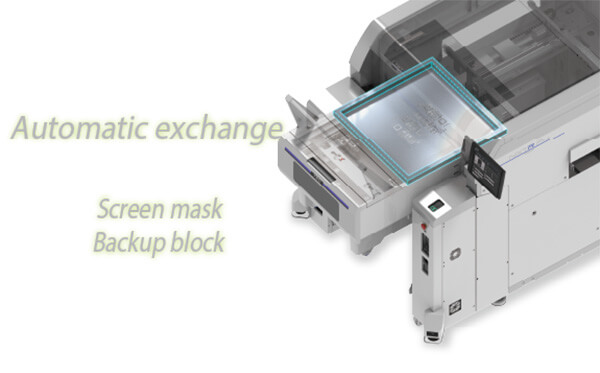

Making changeover work hands free

It is possible to automatically exchange screen masks and backup blocks by using PM Smart Changer.

Setting materials in the PM Smart Changer rack in advance makes it possible to automatically change the materials when changing the production

model.

Changeover work such as collecting and supplying solder when exchanging screen masks, changing the conveyor width, and positioning backup

blocks can be automated.

This reduces the workload on operators and eliminates reworking that may result from human error.

* All are optional other than conveyor width adjustment

No need for test printing

Automatic extraction of print parameters from the database makes it possible to quickly determine printing conditions and start produ

ction without test printing.

It is no longer necessary to look for past performance records and adjust parameters from experience.

This helps to minimize the time until the start of production.

This system is also designed for referencing past quality records from SPI machines, to provide the option of selecting more suitable printing

conditions.

Flexible support for a wide variety of production

Single lane and dual lane production is supported by a single machine accordingly to fit any situation. All kinds of production are flexibly covered;

from producing small panels for smartphones to large panels associated with automotive electronics and network infrastructure.

The NXTR PM supports dual lane production and is highly compatible in line configurations with the NXTR.

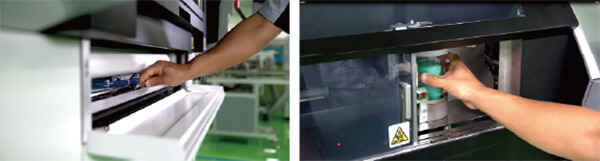

Supplying materials without stopping production

Solder cups and cleaning paper are accessible from the machine front during production for easy exchange.

Equipped with the solder transport mechanism*, the machine transports solder to printing positions during dual lane production.

These features ensure non-stop production in good harmony with material supply.

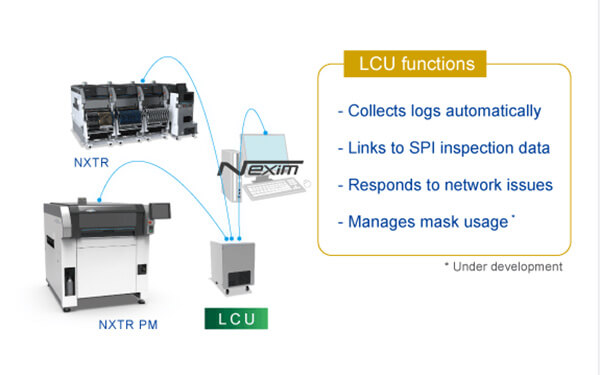

Non-stop production

By automatically saving logs and image data, issues that may cause machine stops and information that can be used for problem solving

are not missed, for faster recovery times.

Furthermore, network conditions are constantly monitored to prevent production stops associated with network issues from occurring.

Smart factory initiative

FUJI Smart Factory offers solutions for a wide range of challenges amidst various production types, which in turn improves factory productivity

and flexibility in parallel with maximizing the QCD performance of manufacturing.

Repeated alignment accuracy 1 | ±0.010 mm @6σ (CPK ≥ 2.0) | |||

Printing accuracy 2 | ±0.020 mm @6σ (CPK ≥ 2.0) | |||

Printing speed | 1 to 300 mm / sec. | |||

Panel size (L x W)

| Single conveyor | 48 x 48 to 610 x 610 mm | ||

Double conveyor | Single conveyance | 48 x 48 to 610 x 510 mm | ||

Dual conveyance | 48 x 48 to 330 x 280 mm | |||

Screen frame (L x W) | 650 x 550 mm, 29 x 29-inch, 750 x 750 mm, 750 x 810 mm | |||

Machine size (L x W x H) | 1,280 x 1,700 x 1,480 mm | |||

Power | 3-phase AC 200 to 230 V ±10% (50/60 Hz) | |||

Air | 0.4 MPa | |||

Air consumption | Single conveyor | 7.7 L/min. (ANR) | ||

Double conveyor | 37.0 L/min. (ANR) | |||

Keyword:

JUKI RS-1R pick and place machine, JUKI RX-7R pick and place machine, Hanwha SM481 Plus Pick and Place Machine, SMT pick and place machine, JUKI Pick and place Machine, Samsung Pick and Place Machine, Yamaha Pick and Place Machine, Panasonic Pick and Place Machine, FUJI Pick and Place Machine, Siemens Pick and Place Machine.

Shenzhen Qituo electronic Co., Ltd provide a full SMT assembly line solutions, including SMT Reflow Oven, Wave Soldering Machine, Pick and Place Machine, SMT Stencil Printer, SMT AOI SPI Machine, SMT Peripheral Equipment, SMT Assembly line, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: wechat whatsapp:+8617748683433, Email: sales@qismt.com

FAQ

1) This is the first time I use this kind of machine, is it easy to operate?

There is English manual or guide video that show you how to use machine.

If you still have any question, please contact us by e-mail / skype/ phone /trademanager online service.

2) If machine have any problem after I receive it, how can I do ?

Free parts send to you in machine warranty period.

If the part is less than 0.5KG, we pay the postage.

If it exceeds 0.5KG, you need to pay the postage.

3) MOQ ?

1 set machine, mixed order is also welcomed.

4) How can I buy this machine from you? ( Very easy and flexible !)

A. Consult us about this product on line or by e-mail.

B. Negotiate and confirm the final price , shipping , payment methods and other terms.

C. Send you the proforma invoice and confirm your order.

D. Make the payment according to the method put on proforma invoice.

E. We prepare for your order in terms of the proforma invoice after confirming your full payment.

And 100% quality check before shipping.

F.Send your order by air or by sea.

5)Why choose us ?

A. Gold supplier on Alibaba !

B. Trade assurance to US$54,000 !

C. Best price & Best shipping & Best service !

Contact:Andy

Phone:17748683433

E-mail:sales@qismt.com

Add: