YAMAHA 3D SPI YSi-SP

“1-head solution” to perform various inspections with a single head

Achieves high-accuracy high-speed inspections using 3D+2D inspection, image resolution switch-over and more

A thorough and extensive machine-to-machine (M2M) solution

Statistical Process Control (SPC) for diverse statistical processing

Optional features to enable handling various products

YAMAHA 3D SPI YSi-SP

YAMAHA 3D SPI YSi-SP

Eagerly awaited SPI from Yamaha Gives your one stop solution from printing machine to AOI

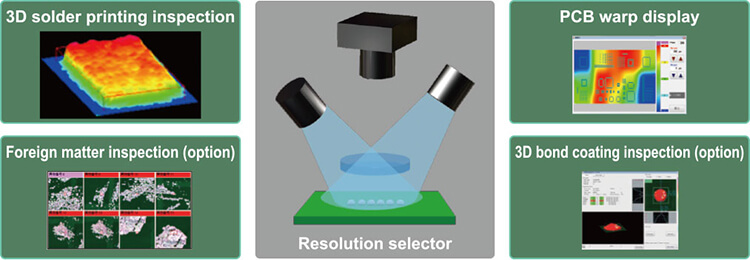

“1-head solution” to perform various inspections with a single head

One head type supports all types of inspections. Eliminate all types of losses such as time and cost to increase your actual productivity.

Achieves high-accuracy high-speed inspections using 3D+2D inspection, image resolution switch-over and more

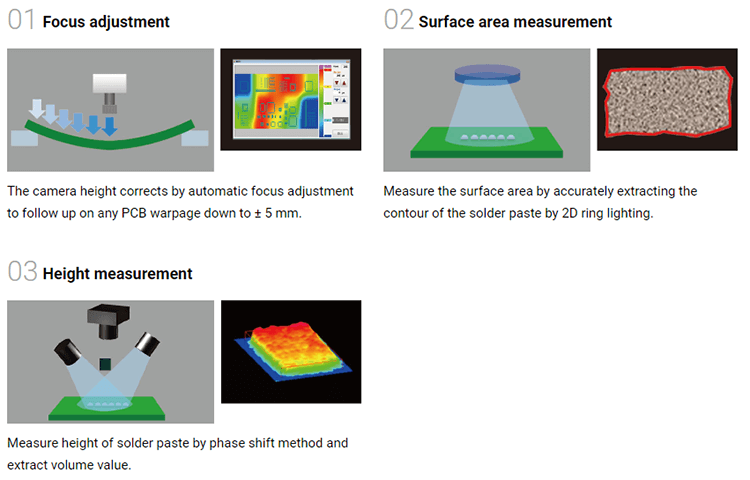

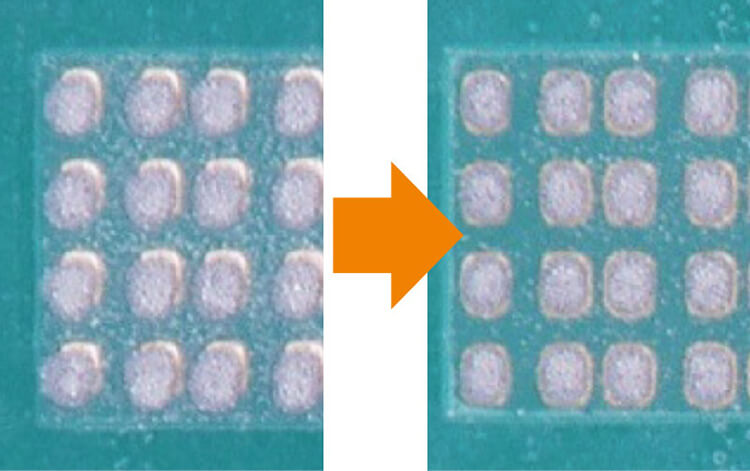

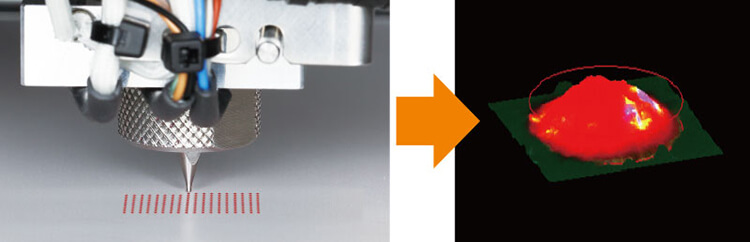

Highly accurate 3D inspections by applying unique 3-step algorithm

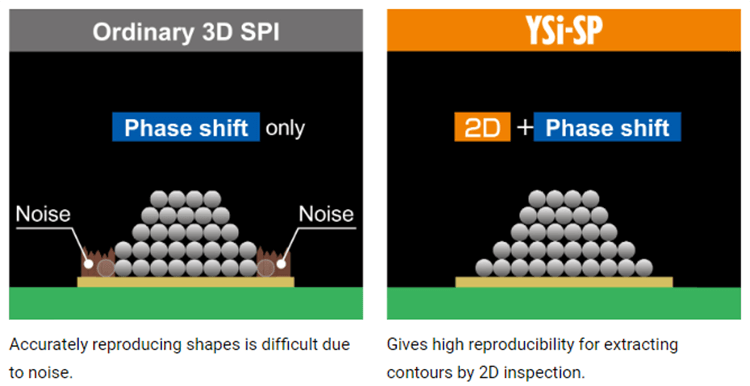

High precision 2D contour extraction

Reproduces accurate shapes by combining with phase shift method.

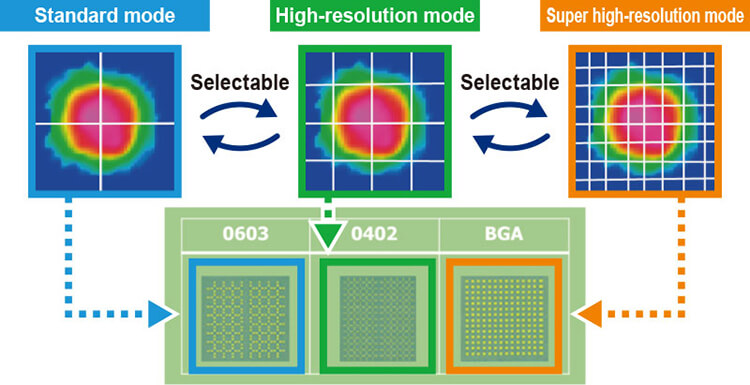

Select from a maximum 3 types of resolution

Super high-resolution technology makes automated inspections on the same type PCB while switching between a maximum of 3 resolution levels Unit flexibly handles components from super-tiny components to large-size components.

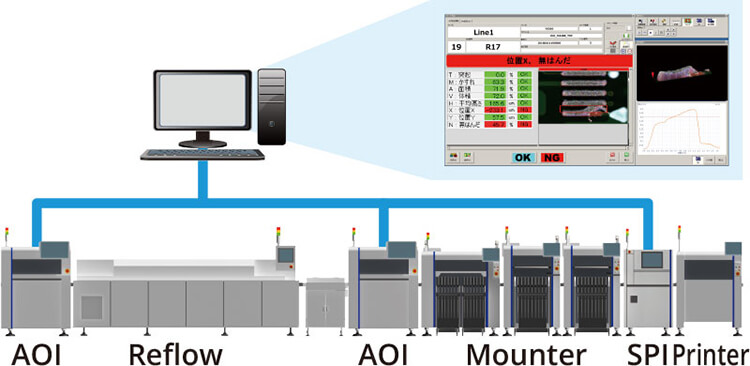

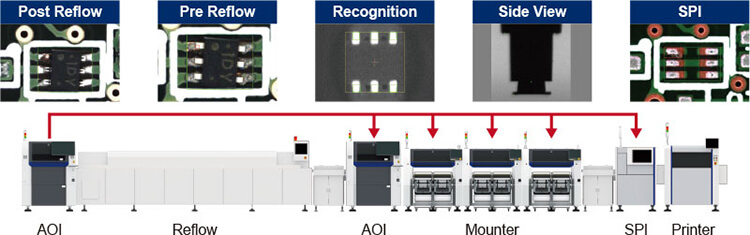

Extensive machine-to-machine (M2M)solution

The Yamaha brand can provide all main equipment needed for component mounting in one package and by linking SPI with each piece of equipment creates a production line having boosted quality and productivity.

Automatic setup changes

Settings such as production line PCB data and conveyor width are sequentially sent from upstream units by scanning ID such as for barcodes listed on PCB and instruction sheets to automatically to shorten the time needed to switch setups and make changeovers.

Feedback print offset

Feedback print offset and initiate cleaning cycle acquired by SPI to the downstream printer to give high print quality.

Remote pass-fail judgment

Automatically converts coating inspection data

Create coating data from the dispenser and send to SPI in just one click!

Simultaneous image display in each process (Process Correlation)

Swiftly pinpoints the process where a failure occurred by displaying images from and the production status of each process simultaneously to support production process quality improvement.

Solder paste printing analysis

Displays link between fluctuations in solder size and solder paste printing status and allows checking the solder paste printer status when defects or problems occur. Streamline quality improvements and line operating rate.

Applicable PCB | L510×W460mm~L50×W50mm (single lane spec) |

*No dual lane specification available. | |

Horizontal resolution (FOV size) | 1) 25μm / 12.5μm / 8.5μm (approx. 50 x 50mm) |

2) 20μm / 10μm / 7μm (approx. 40 x 50mm) | |

3) 15μm / 7.5μm / 5μm (approx. 30 x 30mm) | |

Note : All are standard selection type. | |

Height resolution | 1µm |

Inspection items | Solder paste printing quality (volume, height, area and misalignment) |

Power supply | Single-phase AC 200V–230V ±10% |

Air supply source | Airless specification |

External dimension | L904×W1,080×H1,478 mm |

Weight | Approx. 550 kg |

Keyword:

JUKI RS-1R pick and place machine, JUKI RX-7R pick and place machine, Hanwha SM481 Plus Pick and Place Machine, SMT pick and place machine, JUKI Pick and place Machine, Samsung Pick and Place Machine, Yamaha Pick and Place Machine, Panasonic Pick and Place Machine, FUJI Pick and Place Machine, Siemens Pick and Place Machine.

Shenzhen Qituo electronic Co., Ltd provide a full SMT assembly line solutions, including SMT Reflow Oven, Wave Soldering Machine, Pick and Place Machine, SMT Stencil Printer, SMT AOI SPI Machine, SMT Peripheral Equipment, SMT Assembly line, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: wechat whatsapp:+8617748683433, Email: sales@qismt.com

FAQ

1) This is the first time I use this kind of machine, is it easy to operate?

There is English manual or guide video that show you how to use machine.

If you still have any question, please contact us by e-mail / skype/ phone /trademanager online service.

2) If machine have any problem after I receive it, how can I do ?

Free parts send to you in machine warranty period.

If the part is less than 0.5KG, we pay the postage.

If it exceeds 0.5KG, you need to pay the postage.

3) MOQ ?

1 set machine, mixed order is also welcomed.

4) How can I buy this machine from you? ( Very easy and flexible !)

A. Consult us about this product on line or by e-mail.

B. Negotiate and confirm the final price , shipping , payment methods and other terms.

C. Send you the proforma invoice and confirm your order.

D. Make the payment according to the method put on proforma invoice.

E. We prepare for your order in terms of the proforma invoice after confirming your full payment.

And 100% quality check before shipping.

F.Send your order by air or by sea.

5)Why choose us ?

A. Gold supplier on Alibaba !

B. Trade assurance to US$54,000 !

C. Best price & Best shipping & Best service !

Contact:Andy

Phone:17748683433

E-mail:sales@qismt.com

Add: